Innovations in Advanced Manufacturing Technologies

The world of manufacturing is constantly evolving, driven by innovations in technology and the increasing demands for efficiency, precision, and speed. Advanced manufacturing technologies are revolutionizing the way products are made, enabling manufacturers to produce higher-quality goods at lower costs. From 3D printing to automation and artificial intelligence, these cutting-edge technologies are reshaping the manufacturing industry and paving the way for a future of endless possibilities.

One of the most significant advancements in recent years is the emergence of 3D printing, also known as additive manufacturing. This technology allows manufacturers to create three-dimensional objects by adding layers of material, rather than subtracting or molding it like traditional manufacturing methods. 3D printing has revolutionized product prototyping, as it enables designers to quickly create physical models and test their designs before going into full production. This not only saves time and money but also allows for rapid iteration and innovation. Furthermore, 3D printing has enabled the production of complex, customized products that were previously impossible or prohibitively expensive to make using traditional methods.

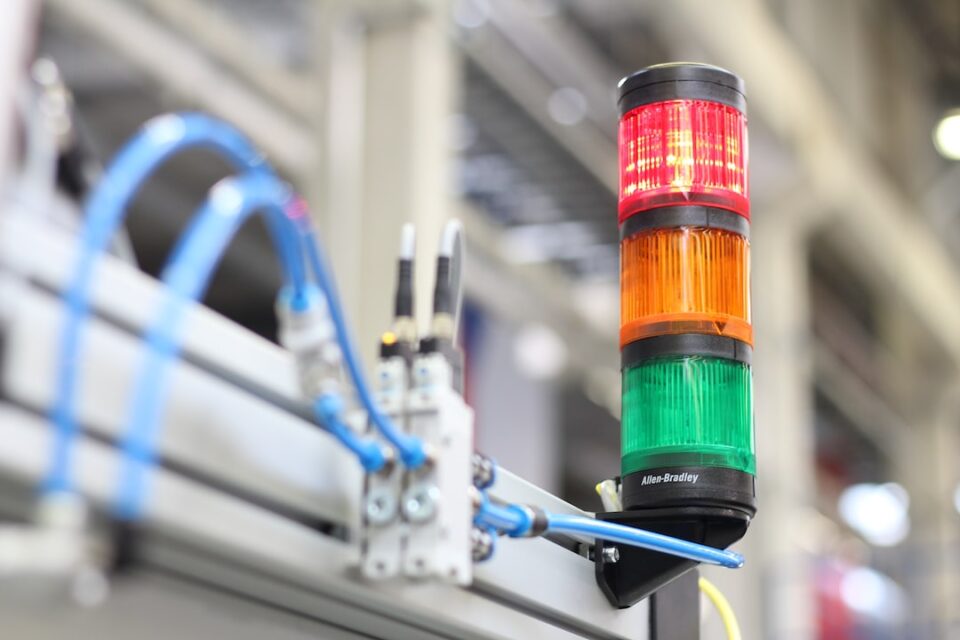

Another advancement is the rise of automation in manufacturing. Automation involves the use of machines and robotics to perform tasks that were previously done manually by humans. This technology has been around for decades, but recent advancements in sensors, machine learning, and artificial intelligence have made automation more efficient and adaptable. Robots with advanced vision systems can now perform intricate tasks with precision and speed, improving the overall quality and consistency of products. Automation also reduces the risk of human error and the need for human intervention in repetitive or dangerous tasks, leading to increased safety and productivity.

Artificial intelligence (AI) is another transformative technology in advanced manufacturing. By harnessing the power of AI, manufacturers can analyze large amounts of data and gain insights to improve their operations. AI algorithms can be used to optimize production processes, predict equipment maintenance needs, and identify inefficiencies in a manufacturing system. This leads to improved efficiency, reduced downtime, and cost savings. AI-powered systems can also self-adjust and learn from past experiences, continuously improving their performance and adapting to changing demands. This technology is revolutionizing supply chain management, as AI algorithms can analyze data from various sources, such as customer demand, inventory levels, and production capacity, to optimize production schedules and logistics.

Another innovation that is shaping the future of manufacturing is augmented reality (AR) and virtual reality (VR). AR and VR technologies allow manufacturers to visualize and simulate complex processes and products in a virtual environment. This enables engineers to design and test products before physical prototypes are built, saving time and resources. Furthermore, AR can be used to provide real-time instructions and guidance to workers on the plant floor, improving productivity and reducing errors.

Integration of advanced manufacturing technologies is also a key focus for innovation. Combining different technologies, such as 3D printing, robotics, and AI, allows for the creation of highly efficient and flexible manufacturing systems. For example, manufacturers can use 3D printing to rapidly prototype parts, and once the design is finalized, they can use automation and robotics to mass-produce the parts with high precision and productivity. This integration of technologies has the potential to completely transform manufacturing processes and supply chains, leading to faster production, reduced waste, and increased customization.

In conclusion, advanced manufacturing technologies are revolutionizing the way products are made. From 3D printing to automation, artificial intelligence, and augmented reality, these innovations are reshaping the manufacturing industry and driving it towards a future of increased efficiency, precision, and customization. Manufacturers who embrace these technologies will gain a competitive edge, as they can produce higher-quality goods at lower costs, optimize their operations, and adapt to changing market demands. The possibilities offered by advanced manufacturing technologies are endless, and we are only scratching the surface of their potential. As these technologies continue to evolve, we can expect even more exciting and transformative innovations in the world of manufacturing.