Digital Transformation in Manufacturing: A Roadmap to Success

In the era of digitalization, the manufacturing industry is experiencing a significant shift towards embracing digital technologies to improve efficiency, productivity, and profitability. This evolution, known as digital transformation, is reshaping the way manufacturers operate and is paving the way for a more agile and data-driven future. In this blog post, we will discuss the concept of digital transformation in manufacturing and provide a roadmap to help manufacturers successfully navigate this journey.

What is Digital Transformation in Manufacturing?

Digital transformation refers to the integration of digital technologies into all aspects of a manufacturing business, including production, supply chain management, customer relations, and data analytics. By leveraging advanced technologies like artificial intelligence (AI), Internet of Things (IoT), cloud computing, and big data analytics, manufacturers can optimize their operations and create a more sustainable competitive advantage.

The Roadmap to Digital Transformation

1. Establish a Clear Vision: The first step towards achieving digital transformation is to develop a clear vision and strategy for the future. Define your objectives, identify the areas that need improvement, and set realistic goals for digital transformation.

2. Create a Digital Culture: To drive successful digital transformation, a company must foster a culture that embraces innovation, continuous learning, and collaboration. Educate and empower your employees to adapt to digital technologies and encourage them to think creatively about how technology can enhance their daily work.

3. Invest in Technology Infrastructure: Investing in the right technology infrastructure is critical for successful digital transformation. This includes robust hardware, software, data storage, and connectivity solutions. Evaluate your current infrastructure, identify gaps, and invest in the necessary upgrades.

4. Embrace IoT and Advanced Analytics: The Internet of Things (IoT) allows manufacturers to connect devices and machines to create a network of real-time data. Collecting and analyzing this data can provide valuable insights into production processes, equipment efficiency, and supply chain optimization. Implement IoT solutions and leverage advanced analytics tools to harness the power of data.

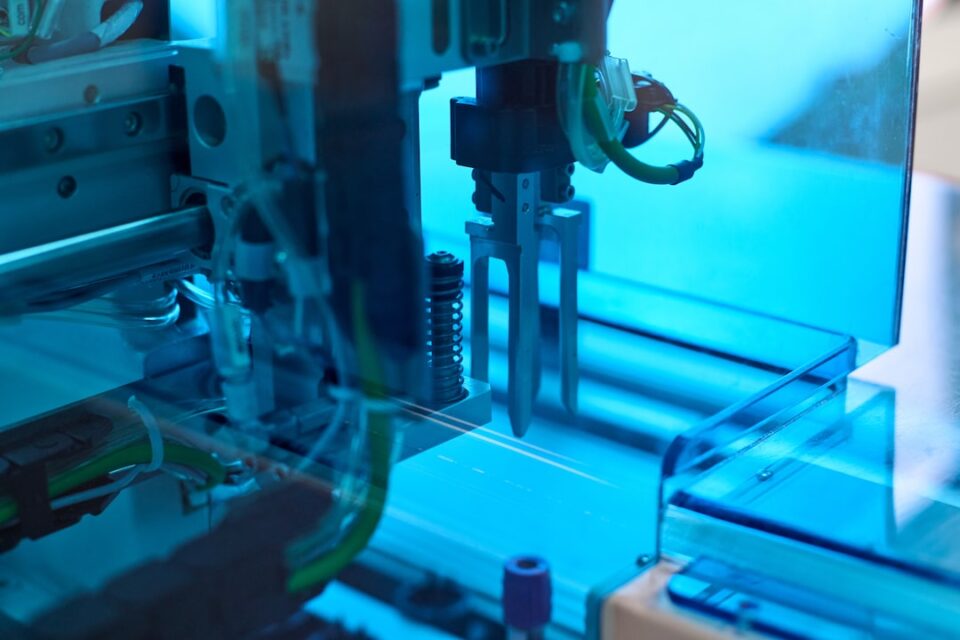

5. Implement Robotic Process Automation: Robotic Process Automation (RPA) can streamline repetitive and manual tasks, freeing up employees to focus on more strategic activities. Identify opportunities for RPA implementation, such as automating data entry, inventory management, or quality control, to improve efficiency and accuracy.

6. Enhance Supply Chain Management: Digital transformation offers enormous opportunities to optimize supply chain management. Implement digital solutions that enable real-time tracking of inventory, automate procurement processes, and enhance collaboration with suppliers and logistics partners.

7. Develop a Data-driven Decision-making Culture: Digital transformation generates an enormous amount of data. To harness the full potential of this data, develop a data-driven decision-making culture. Invest in data analytics tools, build analytics capabilities, and empower employees to make data-backed decisions at all levels of the organization.

8. Ensure Cybersecurity: As manufacturers become more digitally connected, cybersecurity becomes a critical concern. Implement robust cybersecurity measures, conduct regular cybersecurity audits, and educate employees about cybersecurity best practices to protect sensitive information and intellectual property.

9. Continuously Innovate and Evolve: Digital transformation is not a destination but an ongoing journey. Continuously monitor the market, technology advancements, and customer needs to identify opportunities for innovation and improvement. Embrace emerging technologies and adapt your digital strategy accordingly.

Conclusion

Digital transformation has become a necessity for manufacturers to stay competitive in today’s global marketplace. By following this roadmap, manufacturers can align their digital transformation journey with their business objectives and create a sustainable competitive advantage. Embrace digital technologies, foster a culture of innovation, and continuously evolve to thrive in the digital era.